Quenched steel to martensitic structure has considerable internal tension and besides, that has great hardness is also very fragile. In this state it is applicable only very rarely.

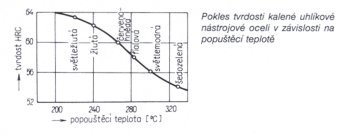

To reduce internal stress and thus the fragility (or get tough structure), is appropriate anneal steelafter hardening. It's heating up to a tempering temperature. For the tempering temperature to 200° C, the strength decreases slightly but decreases much more fragile. At temperatures above 200 °C, a complete disintegration of martensite to ferrite and cementite in very fine form.

This structure is characterized by strength, high resistance and toughness.

Combinated quenching a tempering

Takes place at temperatures from 340 ° C to 650 ° C so that it follows a combined quenching andtempering in quick succession, which is usually one of the most widely used for thermal processingof fasteners. The optimal result is a high tensile strength and sufficient resistance (stiffness), theconnecting member to better resist outside forces. That is why through a combined quenching andtempering heat treated strength bolts also 8.8, 10.9, and 12.9

Surface hardening

In previous methods of heat treatment the thing was to achieve refined steel with high strengthand good notch toughness (highly stressed structural components). Or we tried to obtain a highhardness at relatively low toughness (tools). However, in some cases, especially in structuralcomponents subjected to friction, we require simultaneously high strength and high surfacehardness (see for example, screws). So we want to obtain a good surface wear resistance and corecomponents of great resistance to shock.

| Surface hardening |

|---|

| Surface quenching | Chemical-heat treatment of steel |

| by flame | induction | case-hardening | nitriding | nitrocarburizing |

Surface quenching

For this treatment is suitable carbon steel with content of carbon between 0.45 to 0.60%, which are already considerable quenching hardness. Steels with such a content of carbon in featuresatisfactory toughness and core strength especially in those cases when a component of thesurface quenching normalized either annealed or heat treated. Which means That the corecomponents that are not affected by surface quenching, retains the properties of the previous heat treatment. According to the method of heating the surface layer to distinguish austenizationtemperature surface hardening:

- by flame: (mostly used oxy-acetylene torches, cloudy layer is> 2mm)

- induction: surface layer is heated by current middle and high frequencies with an inductor(coil of a small number of threads of copper tube, through which flows cooling water. passes through the inductor an alternating current of frequency, are formed of alternating magnetic field induction components of eddy currents in the same frequency, which the heated part.selecting frequency can affect the depth of warm layers. It is used mostly for special applications for hardening weaknesses.

Chemical heat treatment of steel

Involves a many ways of processing in which saturate the surface of steels of various elements to achieve desired properties, such as fire resistance, corrosion resistance, wear resistance, etc.

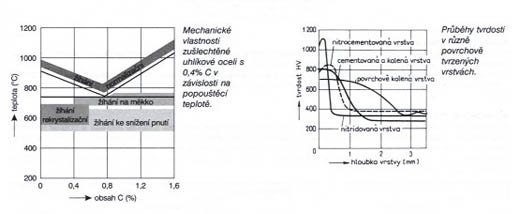

- Case-hardening: most widely used method of chem-thermal processing. The surface of the object from mild steel (with carbon content max 0.2%) is the prin saturation carbon in solid,liquid or gaseous environment over austenizační temperature (in itself only austenite dissolvescarbon) content of the C 0.7 - to 0.9% . Opacity of this layer reaches a high hardness,toughness while maintaining the core. Carburizing layer is 0.5 to 1.5 mm thick.

- Nitriding: steel surface saturation with nitrogen, which reacts with iron and other elementsbeing added intentionally (especially Al and Cr). They are created by hard nitrides, which causea considerable increase in hardness. runs at 500 to 600 ° C.

- Nitrocarburizing: is the saturation of the surface carbon and nitrogen simultaneously incyanide salt bath at temperatures from 750 to 850 ° C, or a gas with the addition of ammoniaat temperatures from 800 to 880 ° C. When the temperature of the carbon is higher, than thecarbon saturation will be higher and vice versa. Then the components tempered in oil, which reduces stress.